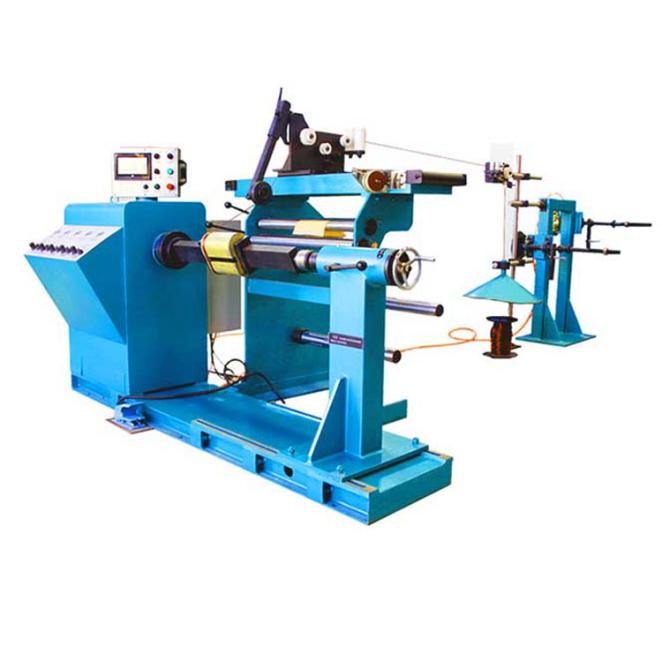

The equipment is mainly composed of: main box, base, automatic wiring rack, interlayer insulation device, electrical control, etc.

1、This machine adopts hard gear gear mechanical transmission system, with high efficiency and less than 70db

2、The motor has an electromagnetic braking function, which is sensitive and reliable.

3、 Stepless speed regulation of the inverter is adopted electrically. The inverter adopts INVT GD300-19-004G-4 or Mitsubishi, Schneider and other higher models. It is controlled by the inverter, so the starting and braking state can be adjusted to make it suitable for the best state of winding.

4、Wide frequency conversion speed regulation, speed regulation preparation, stable.

5、With automatic wiring function.

6、Adopt PLC and servo system Adopt high-end brands such as Mitsubishi or Schneider, high-definition touch-screen display and realize man-machine dialogue, and adopt imported ball screw drive and linear guide to meet the precise wiring.

7、Through high-precision servo system and dedicated line, automatic wiring and winding are synchronized.

8、The pay-off device is provided with a tension function and the tension can be adjusted to meet the requirements of the wire gauge. There is also a pneumatic pressing device to suit the needs of the work.

9、Before winding the wire, you can set the automatic wiring pitch conveniently according to different wire gauges. During the winding process, wire diameter compensation and manual adjustment can be used to adjust the possible errors to ensure the tightness of the coil.

10、The desktop control box is located on the upper part of the winding main box, which is easy to use, simple and has a clear interface.

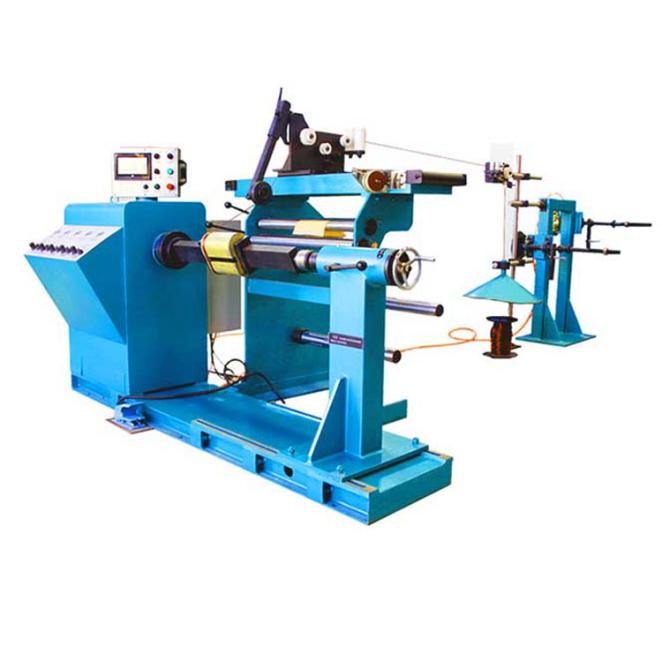

The equipment is mainly composed of: main box, base, automatic wiring rack, interlayer insulation device, electrical control, etc.

1、This machine adopts hard gear gear mechanical transmission system, with high efficiency and less than 70db

2、The motor has an electromagnetic braking function, which is sensitive and reliable.

3、 Stepless speed regulation of the inverter is adopted electrically. The inverter adopts INVT GD300-19-004G-4 or Mitsubishi, Schneider and other higher models. It is controlled by the inverter, so the starting and braking state can be adjusted to make it suitable for the best state of winding.

4、Wide frequency conversion speed regulation, speed regulation preparation, stable.

5、With automatic wiring function.

6、Adopt PLC and servo system Adopt high-end brands such as Mitsubishi or Schneider, high-definition touch-screen display and realize man-machine dialogue, and adopt imported ball screw drive and linear guide to meet the precise wiring.

7、Through high-precision servo system and dedicated line, automatic wiring and winding are synchronized.

8、The pay-off device is provided with a tension function and the tension can be adjusted to meet the requirements of the wire gauge. There is also a pneumatic pressing device to suit the needs of the work.

9、Before winding the wire, you can set the automatic wiring pitch conveniently according to different wire gauges. During the winding process, wire diameter compensation and manual adjustment can be used to adjust the possible errors to ensure the tightness of the coil.

10、The desktop control box is located on the upper part of the winding main box, which is easy to use, simple and has a clear interface.