I.Introduction

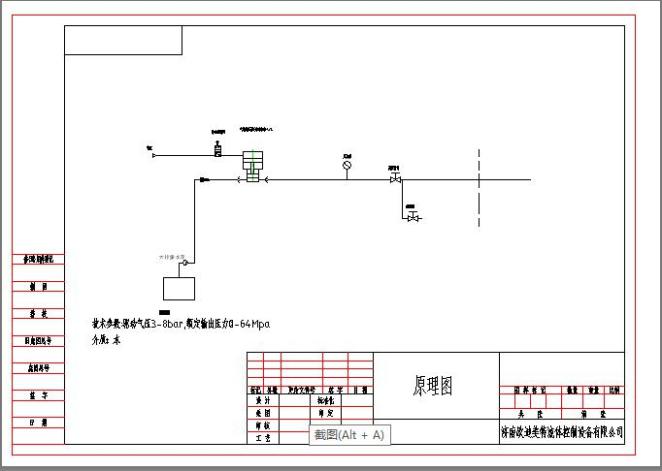

The air driven-liquid booster system is controlled by PLC and outputs a liquid pressure of 0-64MPa according to requirements. Equipped with OGD80 gas drive liquid pump, low pressure pressure gauge, high pressure holding pressure switch, unloading switch, push-button start switch, PLC touch screen control system, can set the upper and lower pressure, and the holding time, if the holding pressure is lower than The lower limit pressure indicates failure, and the buzzer alarms. If it does not fall below the lower limit pressure, it indicates that the test is qualified.

Equipment functions

1. Pressurize the pressurized medium water or oil, and the supercharged pressure is controlled within the allowable division;

2.1 ~ 64MPa liquid test: compressed air controls the driving pressure through the pressure reducing valve, and the compressed air drives the supercharger to perform pressure conversion to output high-pressure liquid;

3. The test pressure can be set within the range of the test. When the test is achieved, the test can be automatically stopped and the alarm beep completed.

4. During the test, if there is a leak or the pressure is too high, it can automatically stop and alarm;The test bench is equipped with an emergency button. In case of an accident, you can press the power to immediately unload and stop the test.

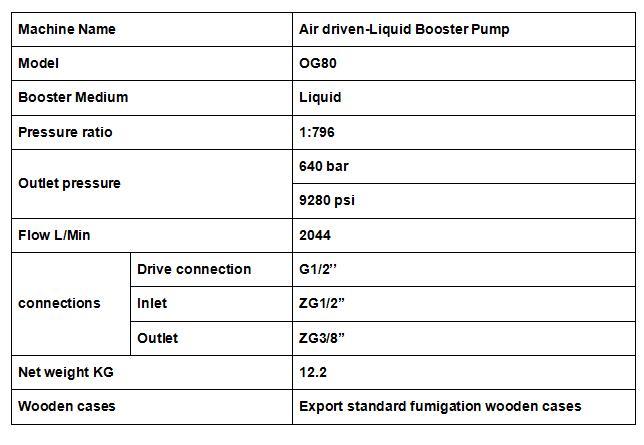

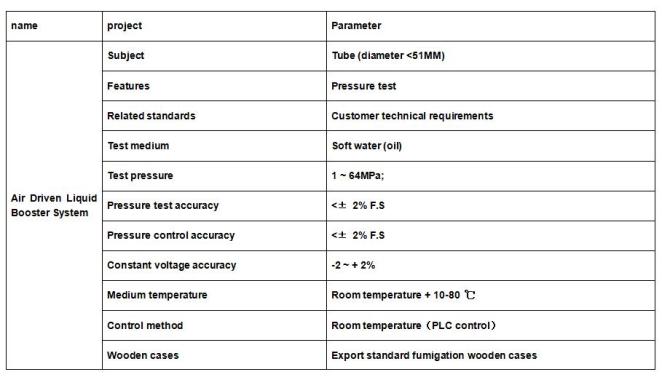

II.Equipment performance parameters

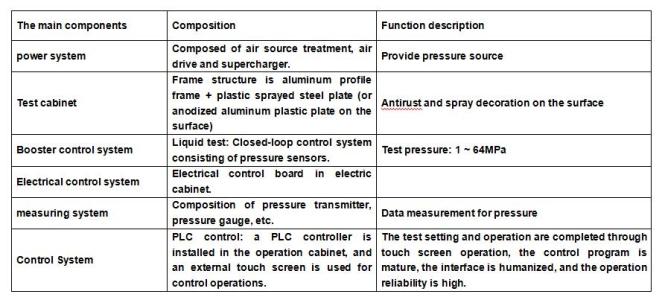

III.Test bench structure

IV.Layout of Machine for reference.

V.Technical Parameter of MLS-OGD80WAir driven liquid booster pump